-

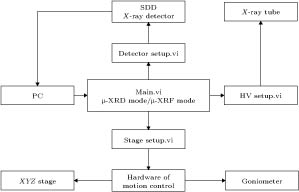

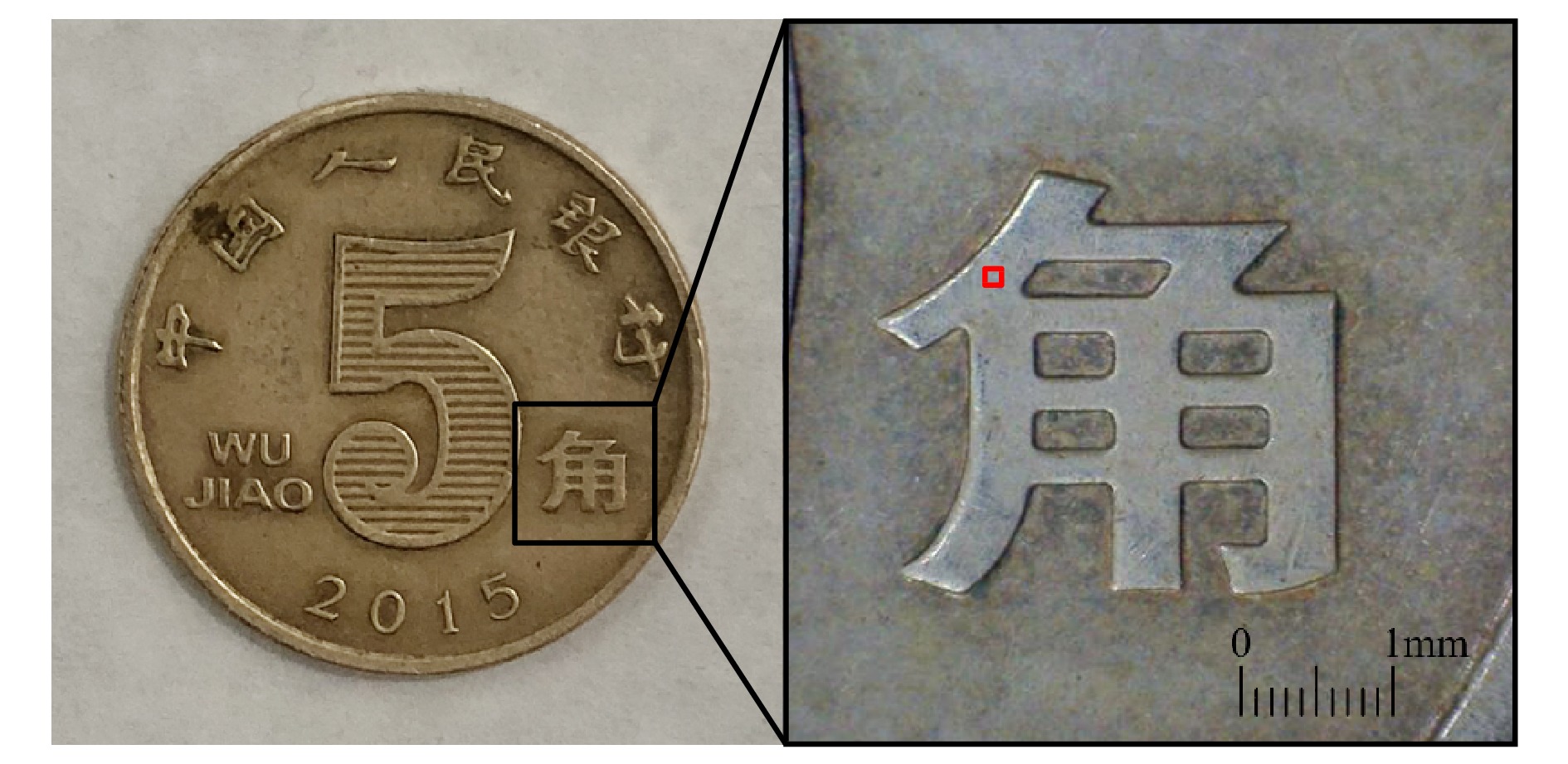

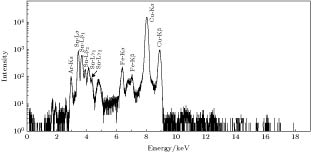

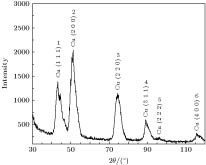

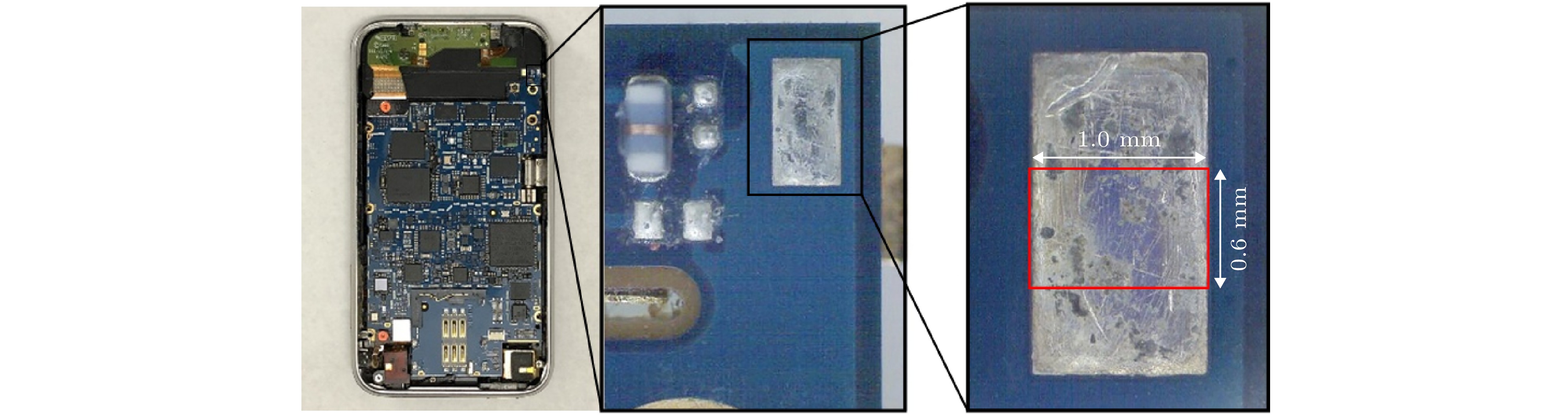

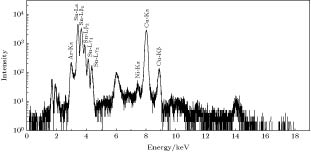

Micro-X-ray diffraction (μ-XRD) plays a significant role in measuring the phase structures of small samples or micro areas of larger samples. In this article, we propose a new type of desktop micro-X-ray diffractometer named μ-Hawk focused by polycapillary optics. It consists mainly of a microfocus X-ray tube, polycapillary optics, receiving slits, a silicon drift diode (SDD) X-ray detector integrated with single/multi-channel pulse analyzer, independently rotating θ-θ goniometer, high precision XYZ sample stage, computer programs developed by LabVIEW codes, etc. The main interface of the program has micro-X-ray diffraction analysis mode and micro energy dispersive X-ray fluorescence analysis mode. In addition, the monochromatization of X-ray, the angular resolution and the accuracy of the results of μ-Hawk are discussed. In order to demonstrate the feasibility of the instrument, the phase of micro area in the middle of the first stroke on the Chinese character “Jiao” from a 5-Jiao coin (Chinese currency) is measured by the μ-Hawk, and the phase of a copper wire 140 μm in diameter is also detected by it. After that, the phase of 1.0 mm × 0.6 mm area on the welding joint of the motherboard from an iPhone is two-dimensionally scanned by μ-Hawk. The θ-θ scanning is performed at each detected point inside the two-dimensional area. Four motors drive the X and Y axis of the sample stage as well as the θ1 and θ2 axis of the goniometer to accomplish the above functions. The results show that the micro energy dispersive X-ray fluorescence analysis mode of μ-Hawk can provide elementary reference information for the analysis of phase structure. Compared with conventional X-ray diffractometer, the μ-Hawk can detect the same diffraction peaks on the coin with lower background. Furthermore, the accurate diffraction peaks can be measured with a lower power and shorter time. The measured results can better reflect the true phase structure of the micro area. Six diffraction peaks and their phases can be clearly identified from the diffraction pattern of the copper wire. For the welding joint, the phase mapping of SnO2 (3 1 2) is acquired through data processing. Therefore, the μ-Hawk can adapt to the micro-X-ray diffraction analysis of small samples or micro areas of samples as well as the two-dimensional scanning analysis of phase mapping. The μ-Hawk exhibits the unique advantages of accomplishing accurate micro-X-ray diffraction analysis, convenient software, low working power, time saving, and small in size. It indicates a wide application prospect in the fields of materials, geosciences and heritage protection.

-

Keywords:

- micro-X-ray diffractometer /

- polycapillary X-ray optics /

- micro-X-ray diffraction /

- micro energy dispersive X-ray fluorescence

[1] Dikmen G, Alver Ö, Parlak C 2018 Chem. Phys. Lett. 698 114

Google Scholar

Google Scholar

[2] Thota S, Kashyap S C, Sharma S K, Reddy V R 2016 Mater. Sci. Eng. B 206 69

Google Scholar

Google Scholar

[3] Zhou X, Liu D, Bu H, Deng L, Liu H, Yuan P, Du P, Song H 2018 Solid Earth 3 16

Google Scholar

Google Scholar

[4] Wang W Q, Ji L, Li H X, Liu X H, Zhou H D, Chen J M 2019 Chin. Phys. B 28 036802

Google Scholar

Google Scholar

[5] Biberger J, Füßer H J, Klaus M, Genzel C 2017 Wear 376– 377 1502

Google Scholar

Google Scholar

[6] Dappe V, Uzu G, Schreck E, Wu L, Li X, Dumat C, Moreau M, Hanoune B, Ro C, Sobanska S 2018 Atmos. Pollut. Res. 9 697

Google Scholar

Google Scholar

[7] Myoung J H, Lee D R, Sung H I, Jeong A Y, Chang Y S, Kim H J, Sun W J, Young W C, Young T H, Myung J K 2018 Eur. J. Pharm. Biopharm. 130 143

Google Scholar

Google Scholar

[8] Shen Y Y, Zhang Y X, Qi T, Qiao Y, Jia Y X, Hei H J, He Z Y, Yu S W 2016 Chin. Phys. Lett. 33 088101

[9] Hampai D, Dabagov S B, Cappuccio G 2015 Nucl. Instrum. Methods Phys. Res., Sect. B 355 264

Google Scholar

Google Scholar

[10] Duan Z M, Liu J, Jiang Q L, Pan Q L, Cheng L 2019 Nucl. Instrum. Methods Phys. Res. Sect. B 442 13

Google Scholar

Google Scholar

[11] Berthold C, Bjeoumikhov A, Brügemann L 2009 Part. Part. Syst. Charact. 26 107

Google Scholar

Google Scholar

[12] Romano F P, Pappalardo L, Masini N, Pappalardo G, Rizzo F 2011 Microchem. J. 99 449

Google Scholar

Google Scholar

[13] Nakai I, Abe Y 2012 Appl. Phys. A 106 279

Google Scholar

Google Scholar

[14] 段泽明, 刘俊, 姜其立, 潘秋丽, 李融武, 程琳 2019 光谱学与光谱分析 39 303

Google Scholar

Google Scholar

Duan Z M, Liu J, Jiang Q L, Pan Q L, Li R W, Cheng L 2019 Spectroscopy and Spectral Analysis 39 303

Google Scholar

Google Scholar

[15] Wrobel P, Czyzycki M, Furman L, Kolasinski K, Lankosz M, Mrenca A, Samek L, Wegrzynek D 2012 Talanta 93 186

Google Scholar

Google Scholar

[16] Hodoroaba V D, Radtke M, Reinholz U, Riesemeier H, Vincze L, Reuter D 2011 Nucl. Instrum. Methods Phys. Res. Sect. B 269 1493

Google Scholar

Google Scholar

[17] Décobert J, Guillamet R, Mocuta C, Carbone G, Guerault H 2013 J. Cryst. Growth 370 154

Google Scholar

Google Scholar

[18] 江超华 2014 多晶X射线衍射技术与应用 (北京: 化学工业出版社) 第169页

Jiang C H 2014 The Technique and Application of Polycrystalline X-ray Diffraction (Beijing: Chemical Industry Press) p169 (in Chinese)

[19] 徐晓明, 苗伟, 陶琨 2014 物理学报 63 136001

Google Scholar

Google Scholar

Xu X M, Miao W, Tao K 2014 Acta Phys. Sin. 63 136001

Google Scholar

Google Scholar

[20] Pradell T, Molera J, Salvadó N, Labrador A 2010 Appl. Phys. A 99 407

Google Scholar

Google Scholar

[21] Baated A, Hamasaki K, Kim S S, Kim K S, Suganuma K 2011 J. Electron. Mater. 40 2278

Google Scholar

Google Scholar

[22] Zhou W, Mahato D N, Macdonald C A 2010 Thin Solid Films 518 5047

Google Scholar

Google Scholar

-

图 5 在接收狭缝宽度为0.1 mm, 样品和探测器之间不同距离条件下测得Si (4 0 0)衍射峰的(a)高斯拟合峰和(b)数据散点图; 在样品和探测器之间距离为70 mm, 不同接收狭缝宽度条件下测得Si (4 0 0)衍射峰的(c)高斯拟合峰和(d)数据散点图

Figure 5. (a) Gaussian fitting peak and (b) data scatter diagram of measured Si (4 0 0) diffraction peak when the receiving slit size is 0.1 mm, and the distances between the sample and the detector are varied; (c) gaussian fitting peak and (d) data scatter diagram of measured Si (4 0 0) diffraction peak when the distance between the sample and the detector is 70 mm, receiving slit sizes are varied.

表 1 测定衍射仪精确度的参考数据与不同角度位置的|Δd/d|

Table 1. Reference data for the determination of diffractometer accuracy and|Δd/d| at different angles.

Reference data Measured data|Δd/d| PDF 2θ/(°) d/nm (h k l) SiO2 (JCPDS 52-0784) 18.0510 0.4910 (0 0 3) 0.0111 Si (JCPDS 27-1402) 69.1300 0.1358 (4 0 0) 0.0003 CuO (JCPDS 48-1548) 113.4850 0.0921 (1 1 5) 0.2596 表 2 两种衍射仪的实验条件

Table 2. Measurement conditions of two diffractometers.

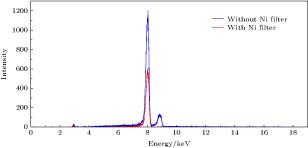

Item μ-Hawk X-pert-pro-MPD Anode material Cu Cu XRD monochromator Ni filter Ni filter Focal size/mm 0.115 × 0.115 1 × 10 HV/kV 30 40 Current/mA 0.5 40 2θ/(°) 10—120 10—90 Step size/(°) 0.1 0.03 Step time/s 11 20 -

[1] Dikmen G, Alver Ö, Parlak C 2018 Chem. Phys. Lett. 698 114

Google Scholar

Google Scholar

[2] Thota S, Kashyap S C, Sharma S K, Reddy V R 2016 Mater. Sci. Eng. B 206 69

Google Scholar

Google Scholar

[3] Zhou X, Liu D, Bu H, Deng L, Liu H, Yuan P, Du P, Song H 2018 Solid Earth 3 16

Google Scholar

Google Scholar

[4] Wang W Q, Ji L, Li H X, Liu X H, Zhou H D, Chen J M 2019 Chin. Phys. B 28 036802

Google Scholar

Google Scholar

[5] Biberger J, Füßer H J, Klaus M, Genzel C 2017 Wear 376– 377 1502

Google Scholar

Google Scholar

[6] Dappe V, Uzu G, Schreck E, Wu L, Li X, Dumat C, Moreau M, Hanoune B, Ro C, Sobanska S 2018 Atmos. Pollut. Res. 9 697

Google Scholar

Google Scholar

[7] Myoung J H, Lee D R, Sung H I, Jeong A Y, Chang Y S, Kim H J, Sun W J, Young W C, Young T H, Myung J K 2018 Eur. J. Pharm. Biopharm. 130 143

Google Scholar

Google Scholar

[8] Shen Y Y, Zhang Y X, Qi T, Qiao Y, Jia Y X, Hei H J, He Z Y, Yu S W 2016 Chin. Phys. Lett. 33 088101

[9] Hampai D, Dabagov S B, Cappuccio G 2015 Nucl. Instrum. Methods Phys. Res., Sect. B 355 264

Google Scholar

Google Scholar

[10] Duan Z M, Liu J, Jiang Q L, Pan Q L, Cheng L 2019 Nucl. Instrum. Methods Phys. Res. Sect. B 442 13

Google Scholar

Google Scholar

[11] Berthold C, Bjeoumikhov A, Brügemann L 2009 Part. Part. Syst. Charact. 26 107

Google Scholar

Google Scholar

[12] Romano F P, Pappalardo L, Masini N, Pappalardo G, Rizzo F 2011 Microchem. J. 99 449

Google Scholar

Google Scholar

[13] Nakai I, Abe Y 2012 Appl. Phys. A 106 279

Google Scholar

Google Scholar

[14] 段泽明, 刘俊, 姜其立, 潘秋丽, 李融武, 程琳 2019 光谱学与光谱分析 39 303

Google Scholar

Google Scholar

Duan Z M, Liu J, Jiang Q L, Pan Q L, Li R W, Cheng L 2019 Spectroscopy and Spectral Analysis 39 303

Google Scholar

Google Scholar

[15] Wrobel P, Czyzycki M, Furman L, Kolasinski K, Lankosz M, Mrenca A, Samek L, Wegrzynek D 2012 Talanta 93 186

Google Scholar

Google Scholar

[16] Hodoroaba V D, Radtke M, Reinholz U, Riesemeier H, Vincze L, Reuter D 2011 Nucl. Instrum. Methods Phys. Res. Sect. B 269 1493

Google Scholar

Google Scholar

[17] Décobert J, Guillamet R, Mocuta C, Carbone G, Guerault H 2013 J. Cryst. Growth 370 154

Google Scholar

Google Scholar

[18] 江超华 2014 多晶X射线衍射技术与应用 (北京: 化学工业出版社) 第169页

Jiang C H 2014 The Technique and Application of Polycrystalline X-ray Diffraction (Beijing: Chemical Industry Press) p169 (in Chinese)

[19] 徐晓明, 苗伟, 陶琨 2014 物理学报 63 136001

Google Scholar

Google Scholar

Xu X M, Miao W, Tao K 2014 Acta Phys. Sin. 63 136001

Google Scholar

Google Scholar

[20] Pradell T, Molera J, Salvadó N, Labrador A 2010 Appl. Phys. A 99 407

Google Scholar

Google Scholar

[21] Baated A, Hamasaki K, Kim S S, Kim K S, Suganuma K 2011 J. Electron. Mater. 40 2278

Google Scholar

Google Scholar

[22] Zhou W, Mahato D N, Macdonald C A 2010 Thin Solid Films 518 5047

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 9604

- PDF Downloads: 96

- Cited By: 0

DownLoad:

DownLoad: